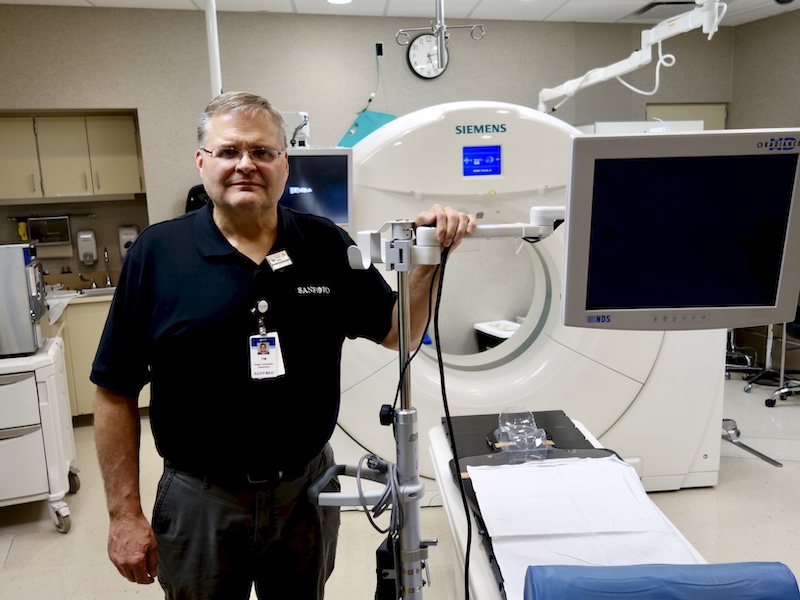

Some places have someone who can fix just about anything, often with stuff most people consider junk. At Sanford Health’s Broadway Medical Center in Fargo, North Dakota, that guy is Tim Miller.

In a day of consultants and answers for anything on the internet, Miller’s approach is simply to listen to doctors and other co-workers before trying to solve problems or other issues.

“You’ve got to know what they’re doing to understand what they need,” he said.

Sanford Health this year launched a formal innovations team, led by former Veterans Affairs Secretary David Shulkin, M.D., to expand on the numerous idea-generating platforms that have been part of the health system for years. Among them: More than 50 inventors develop new approaches, software and devices; a quality and safety control program attracts more than 600 ideas every year on ways to improve patient care; and more than 200 researchers look for answers to vexing problems like type 1 diabetes.

But it’s the countless front-line workers like Miller across the organization’s clinics, hospitals, research labs, long-term care sites and other locations who form the foundation of innovations.

The senior electronics technician with boundless enthusiasm has worked in biomedicine at what is now Sanford Health for more than 22 years. His position requires that he calibrate and maintain highly technical medical devices, some of which are as large as a small room and cost as much as a big house. Complicated machines that sometimes need a simple adaptation to fit the situation or person, which Miller provides.

“Over the years, the favorite part of my job was to design and fabricate accessories for use in departments. I would see a need for a department and would design and fabricate a prototype, and in many instances would end up building it many times over,” he said. “In a sense, it’s a sense of adventure, ‘Hey, what can I make out of this?'”

‘We fixed a lot of stuff’

Like a lot of other innovators, Miller, a Minnesota native, credits his rural upbringing with his creative talent.

“I grew up on a farm, so we fixed a lot of stuff,” he said. “My dad has been gone since ’97 and I remember him fixing stuff. He would say, ‘It might not be pretty, but it works.’ I want it to look good and function well.”

He also spent time helping his father and grandfather in their repair shop.

Miller said that mechanical background prepared him well to also work with highly technical electronics. In a health care setting, he brings an inquisitive nature and a different perspective, which helps him spot solutions to problems that clinical workers might not immediately see.

“A lot of time their focus is patient care, where they can’t see what steps can be taken to make their job easier, which in turn helps patients. That’s my focus,” Miller said. “A lot of stuff I make a prototype and then I tweak it and they said, ‘OK, make me 10 of them.’ A lot of stuff I’ve made for the cath labs and they ask where I bought it. And I said it was made.”

In an operation as large as Sanford Health, there’s a lot of need for that approach, he said.

Reuse and repurpose

Miller has custom-built devices scattered around operating rooms, catheterization labs, radiation oncology, interventional radiation, general X-ray, the general laboratory and even the dietary department.

“I’ll walk into rooms and say, ‘Hey I built that,'” he said. “I take great pride in my innovations and love to see them in action, as it improves the departmental workflow, thus improving the patient care.”

Some of his creations:

- Mobile power strips for operating rooms made out of discarded IV poles.

- Movable monitor stands that swing over the patient, so doctors can look straight ahead at the screen instead of to the side, also made of scrap IV poles.

- Metal rail additions mounted to a table to help an oncology doctor deliver high-dose radiation at the right angle.

- An adjustable board made out of tough, sterile plastic that supports a patient’s arm during the injection of X-ray dyes.

- A heart rate and blood pressure monitor stand made out of an old supply cart and hardware from wall mounts. “I figured the cost savings alone on that was about $5,500 per cart,” he said. “My dad was always like, ‘Waste not, want not.’ As soon as you throw it away you need it.”

Miller said everything meets health standards because he uses only approved materials.

‘He’s got passion’

Jack Westby hired Miller, was his manager for 18 years and now works alongside him as an electronic specialist.

“Everything he does, he makes somebody else’s job easier,” Westby said. “He’s got passion.”

Miller will take a device and design accessories to improve staff and patient workflow. Departments often go to him to see if there could be an accessory designed and built to enhance the equipment design and function.

“The interesting thing is watching him when people come and say, ‘Boy, if we could have this.’ You can see him find parts around the shop and materials and build a prototype. This is where Tim takes his expertise and pushes it to the next level. He is very good at inventiveness and fabrication, and it could be anything,” Westby said.

Miller has worked with numerous departments in the Sanford Health system. The result is always well-engineered and built to exceed the needs of the user, Westby said.

Miller’s current supervisor, electronics director Jay Buchfink, said “innovator” is more than a buzzword for Miller. It’s who he’s always been. “Tim’s done it for years, figured out how to do it.”

As for the future, Miller, who’s 59 years old, said he can’t see himself doing nothing when he ultimately retires. “My dream would be to volunteer at a nursing home and open a repair shop and fix things for people. You learn so much from the elderly.”

Miller shares that philosophy with each email he sends by including a favorite quote from Henry Ford in the signature area: “Anyone who stops learning is old, whether at twenty or eighty. Anyone who keeps learning stays young. The greatest thing in life is to keep your mind young.”

Big and small ideas

Health care is changing dramatically, so Sanford Health needs innovators from top to bottom like Miller, Dr. Shulkin said. All 50,000 Sanford Health and Good Samaritan Society employees, regardless of job or location, should feel they have a voice in helping the organization continually improve how it treats patients, supports employees, and develops new technologies and techniques. In short, countless problems need solutions that best come from the front lines of health care, he said.

Ideas that can be patented will begin that process. Otherwise, Sanford Health will turn any intellectual property rights back to the creator, so he or she can decide whether to develop it. If the idea can’t be commercialized, it might be implemented in other parts of the health system.

More innovation stories

- Innovating is part of Sanford Health’s DNA

- Long-term care innovation: Sanford Health-Good Samaritan

- Sanford Innovations podcast

…

Posted In Innovations, Sanford Stories